Marley and the Mulberry Harbours

With the onset of the War, new housebuilding came to an almost complete stop, roof tile production ceased, and men were dispersed among the armed forces. Some of the Marley factories were requisitioned for such things as armaments manufacture and storage. Marley began to find work for the war effort, making concrete huts, air raid shelters, anti-tank blocks, and concrete ‘mats’ for tanks and vehicles to stand on in unsafe ground.

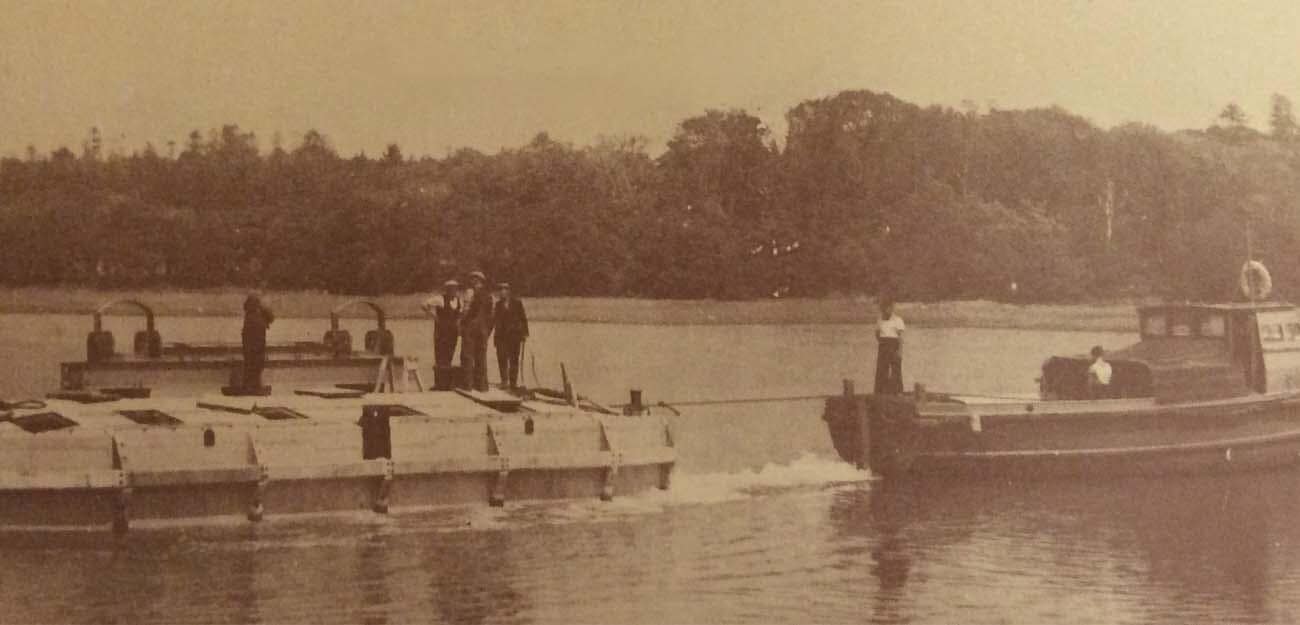

Without doubt, work on the Mulberry Harbour was Marley’s largest wartime contract, as it was for many other building firms. The Mulberry was effectively a floating harbour, fabricated in Britain, then towed across the Channel and assembled off the Normandy coast.